|

SF-10 Self-lubricating

bearings

■

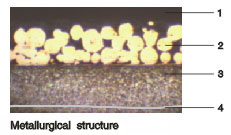

Structure ■

Structure

1、 PTFE

with lead 0.01-0.03mm

2、Porous

bronze 0.2-0.3

mm

3、Steel

backing

4、 Copper/Tin

plating 0.002mm

■

Tech.Data

|

Max.Load

|

Static

|

250N/mm2

|

|

Friction Cofee.

|

0.03-0.20u

|

|

Dynamic

|

140N/mm2

|

Speed limit

|

Dry

|

2m/s

|

|

Oscillating

|

60N/mm2

|

Oil

|

5m/s

|

|

PV limit

|

Dry

|

3.6N/mm2×m/s

|

Thermal conductivity

|

2.41Kcal/M.br.C

|

|

Oil

|

50N/mm2×m/s

|

|

Coeff.of linear expansion

|

27×10-6per℃

|

|

Temp.limit

|

-195℃~+280℃

|

■

Application characteristics

1、 It

may be used where no oil can be applied or oil is difficult to

be applied.

2、It

has the advantage of low wear,low friction and with long life.

3、 Load

will spread over a wider area due to the bearing material's elastic

nature.

4、 Low

stick slip properties ensuring accuracy of machine operation under

low silding speeds.

5、Low

vibration,low noise and non-pollution in operation.

6、 PTFE

and Lead film is transferred to the mating shaft to improve running

properties.

7、 It

can be used in low hardness of mating shaft,so the shafts processing

is easy.

8、The

machine will be compact because of the thin thickness and low

weight of the bush.

9、 Electro

plating is plssible to prevent corrosion.It is widely used in

various sliding motions of defferent kind of machines such as

textile machine,tobacco machines,hydraulic vehicles Automobiles,agriculture

machines and so on.

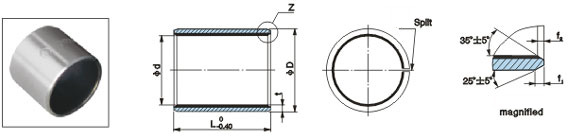

■

Provide

standardized products:Cylindrical bushes P3、P7,flanged bushes P5、P9,thrust

washers P6、P10,flat strip materila P6.

Provide non-standardized products:Cylindrical bushes,flanged bushes,thrust

washers,flat strip material,half bearing, wear plate,SF-10 with

steel bush.

SF-10 Self-lubricating

bearings metric sizes

|

Recommended

|

:OD.D

|

Wall Thickness t

|

f1

|

f2

|

Bearing Length and Part Number

|

|

Shaft Dia.

|

Housing Bore

|

6

|

8

|

10

|

12

|

15

|

20

|

25

|

30

|

40

|

50

|

|

2

|

0

-0.004

|

3.5

|

+0.008

0

|

3.5

|

+0.066 -0.026

|

0.750

-0.080

|

0.4

|

0.3

|

|

|

|

|

|

|

|

|

|

|

|

4

|

|

|

4

|

0406

|

0408

|

|

|

|

|

|

|

|

|

|

5

|

+0.010

-0.068

|

7

|

+0.015

0

|

7

|

1.0

+0.065

+0.080

|

0.5

|

0.3

|

0506

|

0508

|

0610

|

|

|

|

|

|

|

|

|

6

|

8

|

8

|

0806

|

0608

|

0610

|

|

|

|

|

|

|

|

|

8

|

-0.018

-0.029

|

10

|

10

|

0806

|

0808

|

0810

|

0812

|

0815

|

|

|

|

|

|

|

10

|

12

|

+0.018

0

|

12

|

+0.065 +0.080

|

1006

|

1008

|

1010

|

1012

|

1015

|

1020

|

|

|

|

|

|

12

|

-0.016

-0.064

|

14

|

14

|

1206

|

1208

|

1410

|

1412

|

1415

|

1220

|

1225

|

|

|

|

|

14

|

16

|

16

|

|

|

1410

|

1412

|

1415

|

1420

|

1425

|

|

|

|

|

16

|

18

|

18

|

|

|

1610

|

1612

|

1615

|

1620

|

1625

|

|

|

|

|

18

|

20

|

+0.021

0

|

20

|

+0.075 +0.080

|

|

|

1810

|

1812

|

1815

|

1820

|

1625

|

|

|

|

|

20

|

-0.083

-0.041

|

23

|

23

|

1.5 +0.006

-0.026

|

|

|

|

|

2010

|

2012

|

2015

|

2020

|

2025

|

2030

|

|

|

|

22

|

25

|

25

|

|

|

|

|

2210

|

2212

|

2215

|

2220

|

2225

|

2230

|

|

|

|

24

|

27

|

27

|

|

|

|

|

|

|

2415

|

2420

|

2425

|

2430

|

|

|

|

25

|

28

|

28

|

|

|

|

|

2510

|

2512

|

2515

|

2520

|

2525

|

2530

|

2540

|

2550

|

|

28

|

32

|

+0.025

0

|

32

|

+0.086 0.040

|

+0.005

-0.050

|

1.0

|

0.6

|

|

|

|

|

2815

|

2820

|

2825

|

2830

|

2840

|

|

|

30

|

34

|

34

|

|

|

|

3012

|

3015

|

3020

|

3025

|

3030

|

3040

|

|

|

32

|

-0.025

-0.060

|

36

|

36

|

|

|

|

|

|

3220

|

|

3230

|

3240

|

|

|

35

|

39

|

39

|

|

|

|

3512

|

3515

|

3520

|

3525

|

3530

|

3540

|

3550

|

|

38

|

42

|

42

|

|

|

|

|

3815

|

|

|

3830

|

3840

|

|

|

40

|

44

|

44

|

|

|

|

4012

|

|

4020

|

4025

|

4030

|

4040

|

4050

|

|

Recommended

|

OD.D

|

Wall Thickness t

|

t1

|

t2

|

Bearing Length and Part Number

|

|

Shaft Kia.

|

Housing Bore

|

20

|

25

|

30

|

40

|

50

|

60

|

70

|

80

|

100

|

|

45

|

-0.035

-0.060

|

50

|

+0.026 0

|

50

|

+0.086 +0.046

|

|

1.2

|

0.8

|

4520

|

4525

|

4530

|

4540

|

4550

|

|

|

|

|

|

50

|

55

|

+0.080 0

|

55

|

+0.100

+0.066

|

5020

|

|

5030

|

5040

|

5050

|

5060

|

|

|

|

|

55

|

-0.030 -0.040

|

60

|

60

|

|

|

5530

|

5540

|

5550

|

5560

|

|

|

|

|

60

|

65

|

65

|

|

|

6030

|

6040

|

6050

|

6060

|

6070

|

|

|

|

65

|

70

|

70

|

|

|

6530

|

6540

|

6550

|

6560

|

6570

|

|

|

|

70

|

75

|

75

|

|

|

|

7040

|

7050

|

7060

|

7070

|

|

|

|

75

|

80

|

80

|

|

|

7530

|

7540

|

7550

|

7560

|

7570

|

7580

|

|

|

80

|

0 -0.030

|

85

|

+0.086 0

|

85

|

+0.120 +0.070

|

2.5-0.010

-0.060

|

1.4

|

0.8

|

|

|

|

8040

|

8050

|

8060

|

8070

|

8080

|

80100

|

|

85

|

0 -0.056

|

90

|

90

|

|

|

|

8540

|

|

8560

|

|

8580

|

85100

|

|

90

|

95

|

95

|

|

|

|

9040

|

9050

|

9060

|

|

9080

|

90100

|

|

95

|

100

|

100

|

9520

|

|

|

|

9550

|

9560

|

|

9580

|

95100

|

|

100

|

105

|

105

|

|

|

|

|

10050

|

10060

|

|

10080

|

|

|

105

|

110

|

110

|

|

|

|

|

|

10560

|

|

10580

|

|

|

110

|

115

|

115

|

|

|

|

|

|

11060

|

|

11080

|

|

|

120

|

125

|

+0.040

0

|

125

|

+0.170

+0.100

|

|

1.4

|

0.8

|

|

|

|

|

|

12060

|

|

12080

|

120100

|

|

125

|

0

-0.040

|

130

|

130

|

|

|

|

|

|

12560

|

|

|

125100

|

|

130

|

135

|

135

|

|

|

|

|

|

13060

|

|

13080

|

130100

|

|

140

|

145

|

145

|

|

|

|

|

|

14060

|

|

14080

|

140100

|

|

150

|

155

|

155

|

|

|

|

|

15050

|

15060

|

|

15080

|

150100

|

|

160

|

165

|

165

|

|

|

|

|

|

16060

|

|

16080

|

160100

|

|

180

|

185

|

+0.046

0

|

185

|

+0.210

+0.180

|

|

|

|

|

|

|

|

18080

|

180100

|

|

190

|

0

-0.046

|

195

|

195

|

|

|

|

|

|

|

|

19080

|

190100

|

|

200

|

205

|

205

|

|

|

|

|

|

20060

|

|

20080

|

200100

|

|

220

|

225

|

225

|

|

|

|

|

|

|

|

22080

|

220100

|

|

250

|

255

|

+0.062

0

|

255

|

+0.260

+0.170

|

|

|

|

|

|

|

|

25080

|

250100

|

|

260

|

0

-0.052

|

265

|

265

|

|

|

|

|

|

|

|

26080

|

260100

|

|

280

|

285

|

285

|

|

|

|

|

|

|

|

28080

|

280100

|

|

300

|

305

|

305

|

|

|

|

|

|

|

|

30080

|

300100

|

|