| í˝Beaning Selection & Calculation |

| í˝SF-1 Self-lubricating Bearings(SF-10,SF-11,SF-12,SF-13,SF-14,SF-15,SF-16,SF-17,SF-18,SF-19) |

| í˝SF-2 Prelubricated Bearings(SF-20,SF-21,SF-22,SF-23) |

| í˝SF-3 Bimetal Bearings(SF-30,SF-31,SF-32,SF-33,SF-34) |

| í˝SF-4 Wrapped Bronze Bearings(SF-40,SF-41,SF-42) |

| í˝SF-5 Solid-lubricant Bearings(SF-50,SF-51,SF-52,SF-53,SF-54,SF-58,SF-59) |

| í˝SF-6 Ball Retainer Bearings(SF-60,SF-61,SF-62) |

| í˝SF-7 Oil-retaining Bearings(SF-70,SF-71) |

| í˝SF-8 Point-lubricating Bearings(SF-80) |

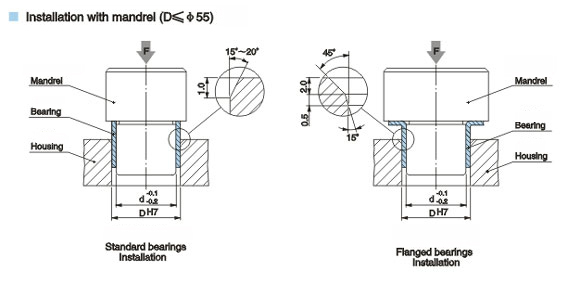

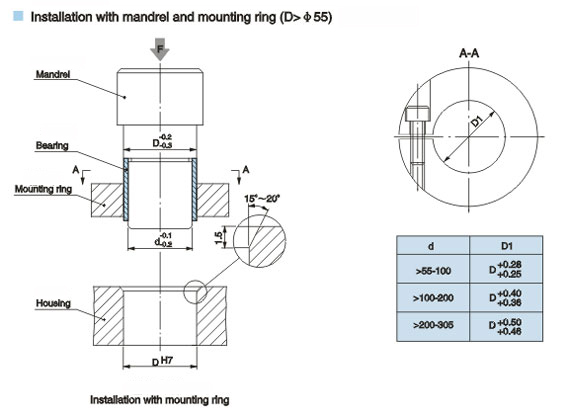

| í˝Wrapped Bearings Installation |

|

| |

| Products

>>íí |

|

|

|

SF-7 Oil-retaining

bearings

|

|

Application characteristicsú║It's

made bronze or iron powder, mold pressed under high pressure

and then sintered under high temperature, and oil is soaked

into the homogeneously spreaded tiny pores of the metal under

vacuum. It's used in domestio electric appliances, electric

tools, textiles machinery.

|

|

SF-71 Bronze

|

SF-72 Iron

|

Provide non-standardized productsú║Cylindrical bushes, flanged

bushes, half bearing, wear plate.

|

SF-80 Point-lubricating

bearings

|

|

Application characteristicsú║Metal backed bronze

with graphite lined bearing materials, sintered layers are

of special copper alloy containing uniformly dispersed solid

lubricants. Suitable for hostile environments, for high load

application which lubricants. Suitable for hostile environments,

for high load application which lubrication, is difficult.

Used in water turbines, injection molding machinery, packing

machines, construction equipment, tire moulds etc.

|

|

compreesive strength

|

320N/mm2

|

|

Friction Coeff.

|

0.1~0.3Ž╠

|

|

Max.Load

|

Static

|

150N/mm2

|

Speed limit

|

0.5m/s

|

|

Dynamic

|

100N/mm2

|

PV limit

|

15N/mm2íĄm/s

|

|

Temp.limit

|

-150íŠ~+250íŠ

|

Hardness

|

>40HB

|

|

| |

SF Wrapped

bearings installation

|

|